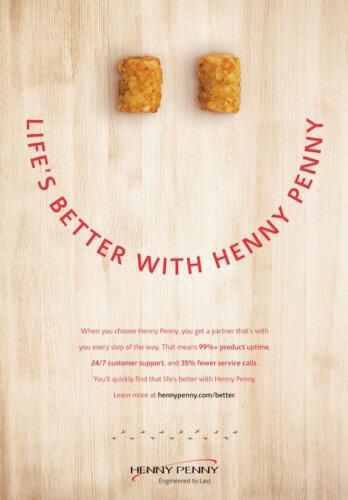

Henny Penny

Remarkable Food Experiences Start Here.

What does it take

to create the most consistently dependable foodservice equipment on the planet today? Proficiency, partnership, and pride.

Proficiency in researching, designing, and manufacturing products for the most successful restaurants in the world.

Partnership with our customers big and small to help them optimize their commercial cooking operations and identify new menu ideas.

And pride from employee-owners, who each have a vital stake in our success.

Henny Penny’s durable foodservice equipment is built for the long haul. But their industry-leading products are just one shining example of their commitment to excellence. From their dedication to innovation and responsive service and support to their deep and long-lasting customer relationships, everything their 1,000+ employee-owners do is engineered to last.

We partner with the best of the best.

“That relationship we build on, it’s family, and that shows with [them] and their products, their employees, and their tech support. Everybody that works in that company – it shows and it’s a quality that McDonald’s builds upon.”

— Johnny Vasquez, Owner/Operator, McDonald’s

LinkedIn Instagram Twitter Facebook YouTube

About Henny Penny

Elevate your culinary operations with the power of Henny Penny foodservice equipment. As a trusted distributor, HP Sales Northeast brings you a comprehensive range of Henny Penny products designed to enhance your kitchen's efficiency, consistency, and versatility. Whether you're a professional chef, restaurant owner, or foodservice operator, our Henny Penny equipment lineup offers innovative solutions that redefine your cooking experience.

From high-performance pressure fryers to versatile combi ovens and beyond, Henny Penny's commitment to quality and innovation shines through in every product. Explore the possibilities, unlock new culinary horizons, and elevate your foodservice business with Henny Penny equipment, only available through HP Sales Northeast.

The revolutionary new Henny Penny F5 is here!

Smart design and effortless operation combine to create a commercial kitchen fryer that’s both intelligent and intuitive.

Open Fryers

Pressure Fryers

Combi Ovens

Holding Cabinets

Breading Systems, Supplies, and Accessories

our customers include…

schedule your kitchen demo today

Come in and take the recipe challenge in our test kitchen. We’ll demo our equipment, help you improve your existing approach, and find what equipment works for you.